GE Aviation drives innovation and digital continuity with Dassault Systèmes

19 October 2018

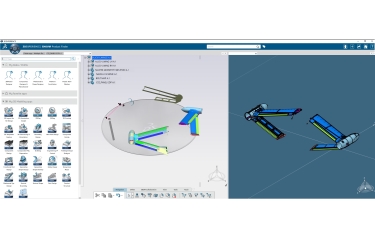

Image courtesy of GE Aviation

Dassault Systèmes is enabling GE Aviation to drive innovation and efficiency across the product development lifecycle of aerostructures through the implementation of its 3DEXPERIENCE platform.

The 3DEXPERIENCE platform is helping GE Aviation to develop a digital thread to enable continuity and collaboration across the business. This includes requirements definition, design, analysis, simulation, manufacturing, qualification and supporting the development of new manufacturing technologies and techniques.

“For GE Aviation Hamble, the implementation of the 3DEXPERIENCE platform supports our ongoing focus on developing innovative aerostructures for the Aerospace industry,” said Paulo Mancilla, Executive Engineering Leader, GE Aviation’s Hamble UK facility. “This enables us to use techniques like digital 3D modelling from design through manufacturing and qualification to create high performance aerostructures for the aviation industry.”

The 3DEXPERIENCE platform provides intuitive 3D applications for product design, analysis, manufacturing and data management in a digital environment. It provides a single collaborative platform to define, share, review, integrate, validate, execute and report, and offers the opportunity to maximise business improvement through digital continuity from concept to delivery.

“Weight, performance and cost continue to dominate the competitiveness of developing and fabricating sophisticated and complex aerostructures for the latest generation of aircraft,” said David Ziegler, Vice President, Aerospace & Defence Industry, Dassault Systèmes. “As a global leader in this field, GE Aviation is constantly innovating and has recognised how the 3DEXPERIENCE platform provides critical technology for this approach. We are very proud to be their partners in this transformation.”

Key benefits of the 3DEXPERIENCE platform for GE Aviation and its customers include:

• Reduced cycle-times resulting from an increase in collaboration between engineering and supply chain functions; driven by a common user interface, which guarantees a unified experience and a shared digital reference that ensures each stakeholder is working on the latest information and in the relevant context. This further enables a model-based enterprise.

• Improved visibility and optimised response-times to customer requests, resulting from the ‘business intelligence’ applications which enable interrogation of real-time information to monitor performance.

• Increased productivity due to the data-centric rationale and the intuitive search capabilities, which simplify data management and promote efficient sharing of information across boundaries.

Contact Details and Archive...