Achieve smarter operation and maintenance in water applications

14 February 2019

Water Treatment Plant (WTP) and Wastewater Treatment Plant (WWTP) operators are increasingly supporting better decision-making by utilising the digitalisation capabilities available through instrumentation and plant management systems. David Lincoln for ABB Measurement and Analytics in the UK, explains how these capabilities can help to boost plant and process performance by providing the data needed for smarter operation and maintenance.

In recent years, a growing array of digital functions have found their way into measuring instruments and analysers that have helped to transform efficiency, particularly in the areas of diagnostics and maintenance.

Successful adoption of digitalisation starts with identifying the right balance of tools and systems. Maximising the value, however, is as much about exercising a mind-set of efficiency as it is about tracking raw numbers.

At the most basic level, WTP/WWTP managers implement digitalisation to improve their snapshot view and understanding of what’s happening in their current operations. At the highest levels, they leverage it strategically for improving customer satisfaction, balancing allocation of capital, and supporting better decision-making in day-to-day business, financial, and water-treatment activities. In all cases, digitalisation provides a platform for enabling more consistent operations without getting users bogged down in the overhead or technicalities of a large data processing structure.

Beyond physical operations, digitalisation also provides ancillary value as a means of adapting to changing patterns in labour force dynamics in water treatment operations large and small.

Getting the most from digitalisation

Taking maximum advantage of the promise that digitalisation has to offer requires thinking beyond existing operations. It requires an attitude where change management, communication, and training are just as important as technology tools. Employing that broader perspective helps users envision more all-encompassing solutions rather than simply automating existing instrumentation functionality.

The strategic benefits offered by more comprehensive data collection and management can include:

Diverse data collection

Some intelligent instrumentation provides added-value data for end users beyond its primary function. For example, some chemical analysers and level detectors provide temperature sensing that can influence better process control decisions. Flow meters that measure conductivity in the pipe can detect changes over time to indicate that more contamination is present and chemical dosing needs have changed.

Dynamic QR

Flow meters that detect air bubbles caused by pump cavitation, or that provide vibration readings, can identify needs for preventive maintenance activities. Cloud-based systems using Internet of Things (IoT) technology also make it easier to access data available from diverse sources – including remote installations.

Comprehensive data analysis

As data collection expands, it increases the risk of overlooking specific ‘nuggets’ of information in the mountains of data generated. Modular software solutions that share inputs from sensor, analyser, and control systems in a more holistic view help WTP/WWTP operations benefit from tighter integration across multiple functions, such as:

• Enterprise asset management/enterprise resource planning – this can help to optimise operation, facility, and asset management in response to the latest process-related data.

• Workforce management – workforce management helps assign employee guidelines for routine maintenance activities as well as responses to system alarms, warnings, and emergencies.

• Asset Performance Management – protects process integrity and equipment longevity through continuous assessment of process instrumentation by optimising both predictive and preventive maintenance planning.

Control-oriented data management

Cloud-based infrastructure helps more people and systems access, monitor, and act upon data specific to WTP/WWTP needs. This includes inputs from process-line instrumentation and signals directed to a variety of control equipment.

Customisable dashboards

Displaying key performance indicators on large touch screen displays empower plant operators to be more aware of and responsive to process variations. Apps running on mobile platforms also make it easier for plant personnel to interact with plant equipment and analytic data.

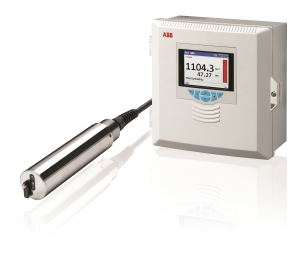

AquaMaster4

Data-driven decision-making

Whatever the infrastructure, the value of digitalisation lies in its ability to provide better perspective for informed decisions. Systems running analytic programs designed specifically for water-plant applications provide insights relevant to key operations. This includes the ability to anticipate changing process trends, to identify and react to potential upset conditions in real time, and to support higher-level organisational objectives.

Reduced cost of measurement

Integrating instrumentation readings within digital management systems improves the time- and cost-efficiency of data collection and its practicality for controlling plant operations. Being able to monitor at a high level in real time, yet still analyse process events in specific detail when necessary, puts plant personnel in a better position to streamline plant efficiency.

Reduced complexity

While more data can be good, more data inputs can bring more complexity. Adopting scalable cloud-based data management systems tailored specifically for water/wastewater applications satisfies changing data collection and analysis needs without tying up internal IT resources or personnel.

The power of prediction

A key benefit of digitalisation is the ability to identify early indications of things that are about to go wrong, rather than simply documenting things that have already gone wrong. The value of this predictive power can be maximised by using historical data trends to program systems to respond at appropriate levels of control needed to maintain optimum performance.

Protect infrastructure with predictive analytics

ATS430 Sensor with wiper

Squeezing maximum value from aging infrastructure requires a strong commitment to tracking key performance indicators. Doing so can help optimise maintenance schedules, protect aging infrastructure, and minimise the risk of unexpected equipment failure. Predictive maintenance analytics are particularly valuable with key instrumentation required for critical round-the-clock operations.

Optimised efficiency for compliance and conservation

Real-time tracking of water streams and equipment performance can indicate shifts in water quality before a complete process upset occurs. This can save on potential fines for noncompliance and reduce the time and expense of bringing plant operations back into balance. Also, in times of water scarcity, any data that improves efficiency helps preserve precious water and energy resources.

Addressing the skills gap

Process instrumentation that can provide analytical summaries alongside detailed readings does a better job of supporting plant personnel with varying levels of experience.

Instruments that encrypt device maintenance and operating conditions within dynamic QR codes make it easier for less experienced personnel to streamline troubleshooting processes. They can simply take a picture of the QR code with their smartphone and forward it to the manufacturer to receive remote support. Meanwhile, more proficient plant personnel can still get the details they desire to exercise their years of troubleshooting expertise.

Summary

Just as no two sites are ever the same, there is no such thing as a single ‘one-size fits all’ digital solution that can just be fitted and left to run by itself. Consequently, deriving maximum benefit from a digital installation requires careful planning and setting of expectations and goals.

In particular, it can often be advisable to take a phased approach, tackling the easiest areas first, before then using the experience gained to find other ways to further integrate the technology into your operations.

ABB can help you to find the best way to maximise your plant performance. For more information, call 0870 600 6122 or email enquiries.mp@gb.abb.com ref. ‘Digitalisation’.

Contact Details and Archive...