Siemens develops a solution for social distancing at the workplace

09 July 2020

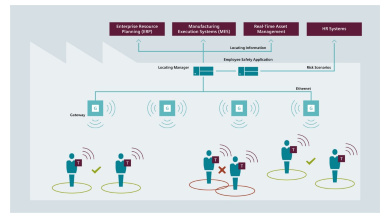

Siemens uses a combination of hardware and software to offer a new solution for the challenges that companies face as a result of the Covid-19 pandemic.

The solution enables companies to quickly and efficiently control how employees interact with one another, with the production line and with the plant setup. The integrated digital twin helps the company to simulate the safety of employees, to test and optimise the setup of work areas, to validate safety measures, and thus to design future-proof production lines.

It is not just a case of re-establishing operating processes with new standards; the safety of each individual employee in terms of social distancing will also be a much more important consideration in future. The Simatic RTLS Real-time Locating System offers companies a means of measuring, monitoring and maintaining social distancing between employees.

Through the interaction of wearable RTLS transponders with infrastructure devices, the movement of employees in all clearly defined areas can be tracked, while observing all applicable data protection regulations. The additional SieTrace software from Siemens processes the location data from the transponders using an algorithm and determines the distances between employees. If the social distance falls below 1.5 metres, a warning signal is sent to all persons involved via the e-link display of the transponder. This ensures that social distancing can be implemented continuously on company premises, and also means that in the event of a risk scenario those employees who could be affected by the risk are identified quickly and reliably. In addition, the real time data provided by the Simatic RTLS can be combined with a digital twin of the real production environment. In the event of an employee contracting Covid-19, companies can then determine possible interaction scenarios between employees. Possible “hotspots” for particular risk areas can be identified quickly and easily. With this precise knowledge of where the risk areas are, safety concepts can be optimised quickly in these areas where there is an actual need. Large cost-intensive hygiene measures across the entire site can then be avoided in favour of a focus on specific areas.

The transparency provided by movement data from the Simatic RTLS can also benefit other applications in the company. The intelligence acquired based on position data for the digital twin provides the company with a comprehensive overview of material flow, order information or possible problem areas for the entire company. With precise location information, time-consuming searches can be minimised or bottlenecks avoided entirely, while throughput and efficiency in the company can be increased. Real-time locating systems support the successful implementation of safety concepts, while also revealing potential for optimisation for innovative production and logistics concepts.

For further information on Simatic RTLS please see: www.siemens.com/rtls

Contact Details and Archive...