The rise of single-pair Ethernet in IIoT (part 3: deploying SPE)

04 May 2022

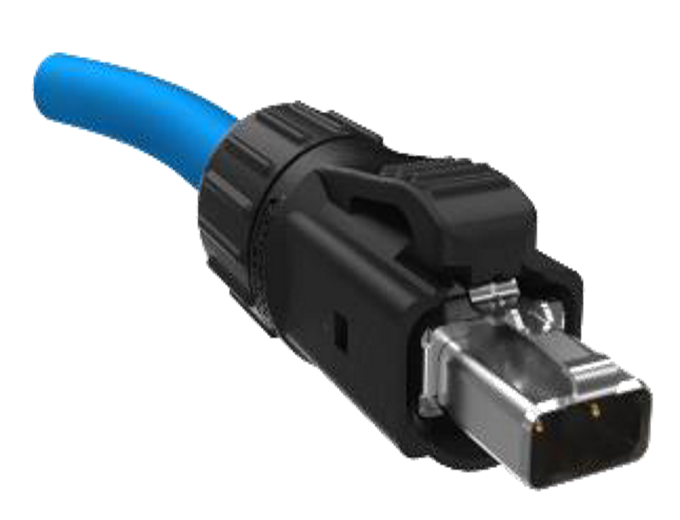

SPE Connector by Amphenol AICC

The operating environment of any manufacturing process can vary tremendously. Extremes in temperature and humidity are commonplace. There are also shock loads and vibration from motors, actuators, and other moving assets to consider.

All of these factors impact the reliability of an overall operation and equipment itself, placing greater importance on the connectivity between those assets and process control equipment.

In terms of connectivity, one of the most noticeable differences between xBASE-T1 SPE and the 4-pair Ethernet standards is the absence of the RJ-45 connector. This connector format was never suitable for industrial applications; even in office environments, the locking mechanism often breaks.

As longer transmission distances are more susceptible to EMC, the IEC 63171 connector standard necessitates a shielded structure that can also operate reliably in harsh industrial environments. In IIoT implementations, where ingress protection is paramount, such as in bottling facilities, two of the six connection methodologies based on this standard have IP67 ratings.

Of these two options, the IEC 63171-5 standard for industrial M8 / M12 connectors has risen in popularity for IIoT SPE implementations. The metric circular connection system is one of the most reliable, resilient, and robust interconnect methods. The M12 connector size is already standard for sensor/actuator cabling or data transmission. With the shift to SPE and demand for miniaturisation, the M8 size, which is a third of the size of an M12 connector, is likely to become increasingly popular.

Accordingly, the SPE mating face integrates into the M8 designs with screw, snap-in, and push-pull locking. For the M12 size, screw and push-pull locking are standardised. An additional benefit to using the established M8 / M12 format for SPE implementations is to ensure market acceptance. It also reduces the necessary investment costs, as many providers have corresponding housing designs in stock.

The switch from a 4 or 8 pole cable into a 2-wire cable represents the next milestone in network technology and will impact all markets and industries. Compared to a four-pair CAT 6 cable, which uses AWG 23 conductors, a single-pair cable is up to 60 percent lighter in weight. Fewer conductors also make the cables thinner, permitting a tighter bending radius during installation and a higher cable density in the rack.

The role of industry consortia in accelerating SPE deployment

SPE delivers many quantifiable benefits to IIoT and industrial automation implementations. The significant advantage of SPE is the consistent IP-based communication with a uniform protocol standard right down to the field level, reducing parameterisation, initialisation and programming time compared to Fieldbus implementations. It uses a miniaturised M8 / M12 interface with thinner, lighter and more cost-effective cabling, capable of surviving the factory floor’s harsh environment. Multiple IEEE 802.3 standards are available to balance bandwidth, power, and reach, with more expected to follow soon.

For new IIoT implementations, SPE with classic industrial Ethernet eliminates the need for intermediate PLCs and protocol converters, or gateways, easing complexity and reducing costs. SPE also provides a relatively low-cost upgrade path when replacing old wired sensors and actuators in existing systems to provide better performance and power, all with one single-pair cable.

With the IEEE 802.3 standards, the Single Pair Ethernet System Alliance and the Single Pair Ethernet Industrial Partner Network industrial consortia are growing the SPE ecosystem, working with members to develop IP-capable endpoint devices and IEC 63171 interconnect technologies.

SPE can replace a big part of the actual existing field bus systems saving weight and space, and reducing installation time. The future of industrial Ethernet, in many IIoT cases, will see the coexistence of single- and four-pair wiring ? SPE connecting to the PoDL-powered field device and classic Ethernet linking seamlessly to the enterprise data centre and production management system. Via its many sensor and connector suppliers, including AVX, Molex, TE Connectivity, Amphenol, and Phoenix Contact, TTI aims to help its customers better understand the SPE standard and implement the technology into their IIoT applications more effectively.

More information on TTI Europe here.

Contact Details and Archive...