Sponsored Article

Artificial intelligence in real time

05 May 2022

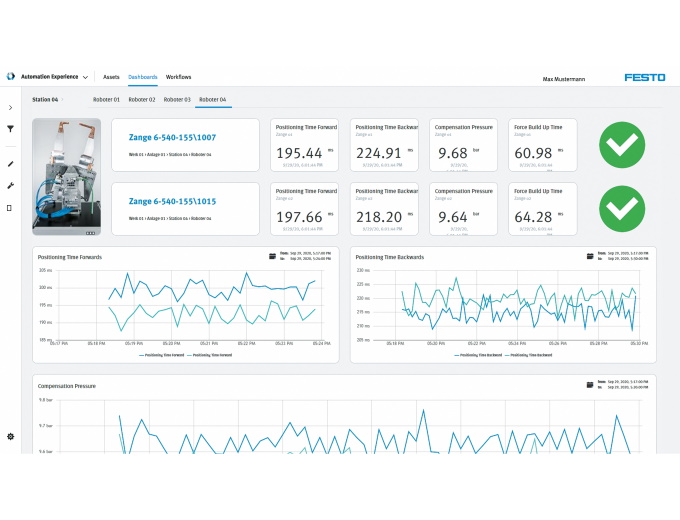

Everything in sight: dashboards for predictive maintenance offer an overview of the machine status

If manufacturers of automation technology want to create real added value for their customers, digitalisation solutions are the way to do it. “That is why Festo developed the Festo Automation Experience, or Festo AX for short,” explains Dr. Oliver Niese, Vice President Digital Business at Festo. Festo AX boosts the performance of machines and systems, thus making customers even more successful.

“Our customer-oriented approach means we have a lot of experience and knowledge of customer applications. We therefore know exactly what software solutions our customers need for their businesses,” adds Niese. After all, Festo not only has automation technology expertise but also industry sector expertise. With the acquisition of the software company Resolto, it also has access to competencies in advanced analytics and artificial intelligence. The software solution Festo AX builds on the combination of these three pillars.

Appetite for digital solutions in machine building

The world is in a state of permanent change. “As individuals, we encounter this change every day in our private lives in the context of digitalisation. These changes will impact on our business world too,” says Niese. This means that anyone who wants to understand the world and the changes in industry needs to be aware that in ten years' time, three quarters of the working population will be so-called digital natives. These people are used to working with digital solutions in machine building. For companies involved in automation technology, it is therefore vital to their continued existence to take this into consideration for future strategies.

To take account of this evolution, Festo developed the solution Festo AX. “It helps our customers to make decisions on the basis of facts,” emphasises digitalisation expert Niese. Festo Automation Experience (Festo AX) is an easy-to-use solution that allows users to extract maximum value from the data produced by their equipment through artificial intelligence (AI) and machine learning.

Analysing data and boosting productivity

Users can increase productivity, reduce energy costs, avoid quality losses, optimise their shop floor and create new business models just by analysing their data with Festo AX. “With the modules Predictive Maintenance, Predictive Energy and Predictive Quality, we implement our customers’ individual solutions together with them,” explains Niese.

Festo AX analyses live data in real time. It can be integrated flexibly into the customer’s system – on premises, on edge or in the cloud. The solution is capable of using the customer’s own expertise according to the principle of “human in the loop”. The user themselves and no one else remains the owner of the collected data.

The data analysis is not just limited to components and modules from Festo itself. “A big advantage on the market is that our software also makes it possible to reliably analyse components from other manufacturers,” stresses digitalisation expert Niese.

Reduce downtimes by 25 percent

For example, a leading car manufacturer has been relying on the high accuracy and efficiency of servo-pneumatic welding guns from Festo for many years. So much so that it has now installed more than 2500 welding gun robots with this technology in the premium brand’s body shops. They have been able to reduce downtimes by 25 percent thanks to a predictive maintenance system from Festo, which is ready for artificial intelligence.

The car manufacturer can schedule repairs to welding guns in non-productive times, thereby increasing the availability of its equipment. The condition of the welding gun can be displayed in the controller. Automated repair orders and even “life cycles” for welding guns are thus easy to create. Filter functions enable comparisons to be made. The early detection of leaks results in energy savings, since energy and maintenance costs play such a major role in the body shop.

Diagnostics for maintenance

Right now, mechatronic system products from Festo for resistance spot welding already process a large amount of data and compress it so it can be used as diagnostics for maintenance. However, it is not enough to just provide and display data. Predictive maintenance based on artificial intelligence will offer additional possibilities in the future compared to traditional condition monitoring approaches. Data from the equipment will be merged with process data and evaluated with analysis models and cloud-based solutions.

The system specialists at Festo have added software to the existing system PCs of the robot cell that collects the welding gun’s diagnostic data and sends it to a collection point in the cloud. The cloud hosts a maintenance application that not only visualises the data in the browser (maintenance dashboards) but also evaluates it in terms of the expected service life.

More information may be found here:

Contact Details and Archive...