Automation tips to reduce energy costs

28 October 2022

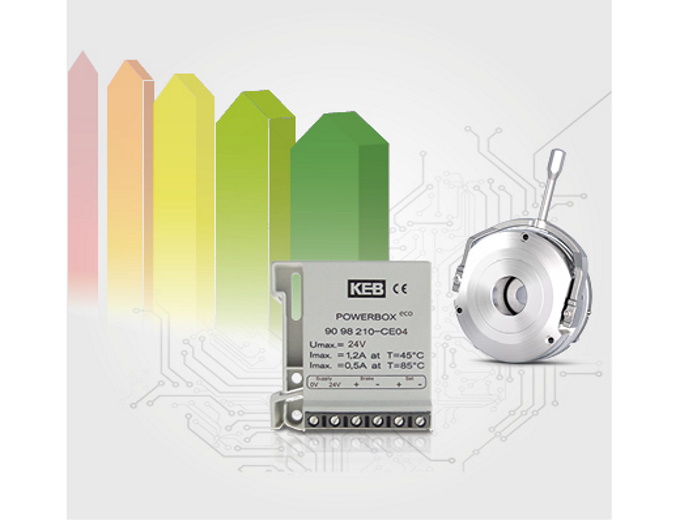

The Powerbox Eco control module for brakes

The cost of electricity, gas and heating oil have risen dramatically worldwide and are placing a considerable burden on plant and machine operators.

More than ever, the question arises of how electricity can be saved without major restrictions on daily operation.

Power supply and regeneration

Energy is often burnt up in braking resistors. This increases the risk of fire, and wastes precious energy. Cyclically-occurring processes, in particular, have a high potential of regenerative energy that can be used easily and efficiently. Where masses are decelerated, supply and regeneration can be considered. With COMBIVERT R6 regenerative units, for example, KEB offers the possibility to return the regenerative energy of drive controllers into the supply network.

The COMBIVERT R6 is designed for the supply and energy regeneration of individual or several drive controllers and can be used for all common supply voltages of 180...528V AC, 50/60Hz. Most units are compact and lightweight and are often supplied with an integrated pre-charging circuit along with optional choke or harmonic filter. As braking resistors are no longer required, supply and regeneration units can reduce the risk of heat/fire in sensitive areas, as well as reducing the cooling requirements of the environment. Optional fieldbus interfaces are normally provided as well as freely configurable inputs and outputs. For some applications, users can even fit energy meters in order to validate their energy savings.

COMBIVERT F6 drive controller

Energy-saving braking

Electromagnetic holding brakes are energised, and thus open most of the time during operation. Only in emergency situations are they switched off. In applications where the brake is energised for a lengthy period of time, it heats up considerably and requires a corresponding amount of energy. This is where a control module for brakes, such as the Powerbox Eco from KEB, comes in. It reduces the nominal voltage required to release the brake to a sufficient holding voltage.

This can lower the energy requirement and reduce heat generation by up to 94 percent. For driverless transport systems, for example, the Powerbox Eco ensures a longer range thanks to the energy savings. Medical technology also benefits from the lower heat generation of the brakes in patient couches.

Efficient pairing of servo pumps and drive controllers

The use of KEB frequency inverters ensures energy savings in numerous applications. This is also the case in combination with servo pumps, which can vary the speed of hydraulic pumps in combination with drive controllers and compact DL4 servo motors. In this way, oil quantities and pressure can be optimally adjusted to the requirements of the machine. Hydraulic pumps that use oil as fluid are often operated via asynchronous electric motors with a fixed speed on the mains. In this case, proportional valves regulate the oil quantity and oil pressure.

Bistable clutches from KEB maintain the switching state (open or closed) without any further energy supply

The problem is that a high proportion of energy is introduced into the system as heat. Based on this, (multi-) servo pump control function of the COMBIVERT F6 drive controller offers the advantage of being able to reduce noticeably the energy requirement, by optimally adjusting the oil quantity and oil pressure. The cycle-time of an injection moulding machine, for example, can also be reduced.

Bistable clutches: up to 99 percent less consumption

KEB offers bistable industrial clutches for various applications, which have the function of maintaining the switching state (open or closed) without any further energy supply. The energy-optimised switching takes place via a short current pulse, which is used exclusively to change the switching state. Depending on the duty cycle, energy savings of up to 99 percent can be achieved, compared to conventional clutches. In door flap systems and air conditioning compressors, for example, bistable clutches are ideal for battery operation.

More on KEB here.

Contact Details and Archive...