Cut unplanned downtime by making maintenance predictable with igus smart plastics. Intelligent cables that predict their service life on automated assembly plants, automotive production, heavy robotics, material handling, pick & place, cutting machines and electronics manufacturing.

READ MORE

igus smart plastics make maintenance intelligent

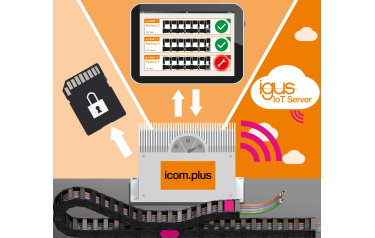

‘Industry 4.0’, ‘Internet of Things’ and ‘Smart Factory’ – these concepts are no longer a vague promise of what is to come. Instead of planning maintenance at fixed intervals or reacting to failures or faults, continually monitoring the health of a machine enables predictive maintenance. Repair or replacement is then only carried out whenever it is actually necessary. At the same time, unscheduled shutdowns and the associated costs can be eliminated.

READ MORE

Ethernet robot cable from igus enables fast and reliable communication

igus has introduced a family of Ethernet/CAT5 chainflex cables, the CFROBOT8.PLUS, designed specifically for 6-axis robots.

READ MORE

igus drylin delta robot coming to a location near you

The drylin delta robot is now on tour; there are live performances at business venues up and down the UK and Ireland, from Aberdeen to Bristol and Dublin to Galway. Last week, skilled igus engineers toured Yorkshire and Leeds, demonstrating the drylin delta robot as a low-cost automation solution for repetitive tasks, such as pick and place, simple assembly, and inspection tasks.

READ MORE

Intelligent smart plastics as active shapers of smart factories

As a manufacturer at the forefront of engineering plastic technology, igus is going through a digital development process and is increasingly orienting its products towards use in smart factories. The aim is to make the maintenance and repair of its plastics more efficient and cost-effective.

READ MORE

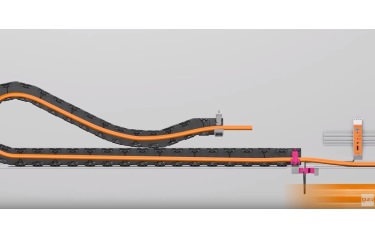

isense CF.P adds more intelligence to smart plastics

Tensile forces acting on the cables within an e-chain system can significantly reduce the service life. The CF.P system picks up any excess forces at the strain relief section and indicates the need for action in a timely manner.

READ MORE

Welcome to the Internet of Everything

The Internet of Things (IoT) has moved from the margins to the mainstream in manufacturing plants across the UK. The killer application, in many of these cases, is maintenance. The availability of smaller and more powerful sensors, along with ubiquitous connectivity, means data can be collected from a wide range of factory equipment, and analysed to spot performance patterns and trends.

READ MORE

igus’ robot handles the most delicate of tasks

In this eggs-cellent video, we see a drylin delta robot in final preparations for Easter. The cost-effective and lightweight modular system can be used for the most delicate of pick-&-place tasks, even collecting Easter eggs.

READ MORE