How ready is your customer for Industrial IoT? Part 1: Industrial networks

29 June 2018

Shutterstock image

What do engineers need to know about the IIoT? A three-part series by Cisco highlights priorities for planning your infrastructure readiness. In Part 1: how network automation, interoperability and intent can enable industrial customers to achieve their business objectives.

The key to any successful industrial-digitisation project lies in its production data

Without the correct data, securely extracted from a myriad of sources and delivered to the correct application at the correct time – industrial customers will not be able to improve equipment availability, enhance productivity, improve quality, lower costs, or innovate more quickly.

The network is the digital core that securely manages data to make Industry 4.0 possible (see “What’s in a name?”).

What do you need to understand as an engineer to make this digital core happen? This article explores three trends: automation, interoperability and intent.

What’s in a name? Industry 4.0, Industrial Internet of Things, Time-Sensitive Networking and more…

The Industrial Internet of Things has many names. Where does the industrial internet end, and digital manufacturing begin? What is the difference between Industry 4.0 and the Internet of Things?

Cisco defines the Internet of Things (IoT) as the connection of people, processes, data and things over an IT network, such as (and including) the internet.

The Industrial Internet of Things (IIoT) is the extension of the IoT into industrial environments. These environments require specialised products and solutions that have been ‘ruggedised’ to operate in extreme situations. Since many operational-technology environments run on legacy infrastructure technologies (e.g. production-line equipment), disparate communication protocols will require interoperability solutions in order to communicate.

Industry 4.0 is the fourth phase of the industrial revolution, in which new combinations of cyber-physical technologies are enabled by IIoT.

IEEE 802.1 Time-Sensitive Networking (TSN) is an enabler of cyber-physical systems. TSN is the foundation to provide connectivity to time and mission critical industrial applications on converged networks of operations technology and information technology. TSN meets these requirements by providing interoperability via open standards. TSN provides synchronisation and supports real-time control over a single standard Ethernet network.

For more on these topics, read “5 Terms Explained: Digital Manufacturing and the Industrial Internet of Things” and follow @Cisco_IoT

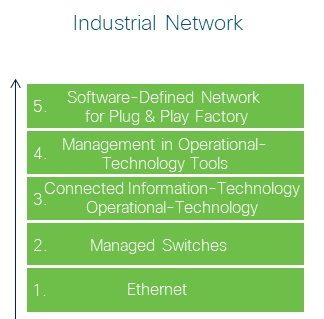

Automation and interoperability for industrial networks

Digital transformation and a proliferation of IoT devices require a new, intent-based approach to networks that meets customer demands for secure, actionable insight into production environments and the supply-chain.

Industrial customers have traditionally faced standards- and interoperability-issues at the foundation (Ethernet) layer of fixed-network industrial connectivity, caused by different industrial-Ethernet protocols (EtherNet/IP, PROFINETv2, CC-Link etc., see “Time-Sensitive Networking”).

There is now more standardisation and interoperability across different transport layers – wired, wireless or cellular [see “Standardisation: interoperable IoT becomes the norm”].

Time-Sensitive Networking (TSN)

TSN fills an important gap in networking standards, by providing secure, guaranteed-latency and performance-delivery for critical applications in industrial environments in the form of an open, Institute of Electrical and Electronics Engineers (IEEE) Ethernet standard. TSN can now combine with the Open Platform Communication Unified Architecture (OPC UA) data-exchange standard, making it easier to:

• share real-time control data among machines from different vendors across a converged TSN network

• update production data in real-time, distributed networks.

Because TSN is delivered over standard industrial Ethernet and guarantees network performance for critical communications, control networks can take advantage of best practices for security that have been developed into Ethernet for decades.

The ultimate goal? A plug-and-play environment for end users in operational-technology (OT) roles, who do not require Information Technology (IT)-networking expertise to provision and manage an industrial network.

This is particularly important in the “extended enterprise” of industrial environments (warehouses, distribution, supply-chain and more), where users can benefit from automation to reduce cost and quality-of-service assurance to make business processes more reliable.

Standardisation: Interoperable IoT becomes the norm

Industrial Networks

By Chris Steck, Head of Standardisation, IoT & Industries, and Maciej Kranz, VP Strategic Innovation, Cisco

The growth of devices and the business need for links between them has made for a wild west of communications in IoT. The whole point of IoT itself is to work together for business benefits. That’s why standards are so important. Without standards, there cannot be interoperability. And without interoperability, benefits will be hard to find. The industry has been evolving rapidly from a collection of overlapping standards, semi-standards, specialised and proprietary technologies into true interoperable standards. To date, such efforts have been focusing on three standardisation groups:

• Interest groups in IEEE, Internet Engineering Task Force (IETF) and other horizontal standards bodies are working to evolve existing horizontal standards to meet IoT requirements. Time Sensitive Networking in IEEE is a great example of evolving the Ethernet standard to meet manufacturing motion and safety requirements. This effort also meets in-car network requirements for driverless vehicles.

• Vertical industry groups are migrating specialised or proprietary technologies to open standards. They are also standardising foundational data fields essential for scalable data collection – for example, they are establishing a standard way to express “temperature” or “pressure” values. This effort is starting with controller-specific data and then moving to telemetry and diagnostics.

• Various consortia are developing frameworks and driving interoperability across their members’ implementations. One example is the OpenFog Consortium, which released the OpenFog Reference Architecture earlier this year.

In 2018, standards organisations will continue to consolidate and cooperate to clear barriers to enterprise and industrial IoT. Instead of standards groups trying to be all things to all industries and use cases, a realisation that there is no single IoT – and hence no one-size-fits-all IoT standard – is leading to cooperation and a reduction in duplicated efforts as different groups tackle more focused challenges.

For example, with the release of the Open Connectivity Foundation (OCF) 1.3 specification, consumer goods manufacturers can now choose a secure, standards-based approach to device-to-device interactions and device-to-cloud services in a common format, without having to rely on, or settle for, a proprietary device-to-cloud ecosystem.

Enterprise IoT providers will also begin to leverage OCF for device-to-device communications in workplace and warehouse applications, and Open Mobile Alliance’s Lightweight Machine-to-Machine (LwM2M) standard will take hold as the clear choice for remote management of IoT devices.

In Industrial IoT, Open Process Communication’s Unified Architecture (OPC-UA) has emerged as the clear standard for interoperability, seeing record growth in adoption with over 120 million installs expected as 2017 draws to an end. It will continue to grow into new industrial areas in 2018 driven by support for Time Sensitive Networking.

For more on this topic, read “IoT in 2018: Time for Business”, and “IoT Technologies: are they making the grade?”

Extending intent-based networking to the Internet of Things

Cisco’s research indicates that by 2020, 46 percent of network devices will communicate machine-to-machine. Although the technical challenges are substantial, ultimately IoT will force a fundamental change in how networks are managed.

The network industry’s transformation to Intent-based Networking allows network professionals to manage the on boarding and administration of network-connected devices at scale. Through an intent-based approach, IT teams can identify, locate and set policy for IoT devices, then scale policy activation across IT and lines of business, and finally provide real-time insights for more efficient operations.

Read more by Scott Harrell (Senior Vice President and General Manager of Cisco’s Enterprise Networking Business) about how industrial-network managers can increase the number of IoT devices that can be automatically classified and identified, including those that use industrial and building protocols like BACNet, Profinet, CIP, and Modbus.

About Cisco and Routeco

Cisco provides the simple, intelligent, secure platform for industrial customers to improve business operations through Industry 4.0:

Routeco is an IoT Industry Expert Specialised Partner of Cisco. With experience of industries such as manufacturing, energy and utilities, travel and transport, connected safety and security, Routeco’s understanding of Cisco’s IoT platform provides industrial customers with the IoT solution they need.

About the authors:

Gordon Davies, Marketing Manager, Cisco with contributions from:

Cisco Industries Marketing

Cisco IoT Go-To-Market

Check out Part 2 which addresses industrial wireless

Contact Details and Archive...