How ready is your customer for Industrial IoT? Part 2: Industrial Wireless

29 June 2018

Shutterstock image

What do engineers need to know about the IIoT? This three-part series by Cisco highlights priorities for planning your infrastructure readiness. Part 1 addressed how to bring automation, interoperability and intent to your network. In this Part 2: industrial wireless – why and where to go wireless in your industrial operations.

Designing industrial wireless for productivity and collaboration

Wireless networks are increasingly prevalent in industrial environments, where wired and wireless solutions are complementary, depending on the use case. While machines have typically been connected via a wired connection, in some locations cable may not a practical solution. Business requirements, such as short-term or fast expansion to new buildings (factory/distribution-logistics space) may mean wireless is a better choice, especially for tasks that are more tolerant to variable-access time, such as:

• location-based services for asset-tracking and telemetry throughout the supply chain

• monitoring hard-to-reach locations such as machinery-in-motion

• mobilising expert workers for collaboration in harsh environments

• worker-safety (embedded wearables, signage)

Reliable and effective industrial wireless is possible, but requires careful planning. The process is more complex than in enterprise settings, but can extend the benefits of a secure, policy-based enterprise network consistently across an organisation, from the data core to the “extended enterprise”: factory floors, distribution centres, supply-chain infrastructure, warehouses, parking.

Tips for successful implementation of industrial wireless

Every industrial environment has its own challenges. From challenging building layouts to harsh environmental conditions, each is different. And if you fail to account for these conditions, your wireless project may fail.

To ensure you get it right the first time:

1) Start with a site survey. Software makes deploying factory wireless considerably easier. However, those tools can’t stand alone. They may miss nuances related to layout, critical locations, coverage, and planning. That’s why every industrial wireless deployment should start with a site survey. This simple first step sets your wireless project up for success. An effective site survey helps determine critical elements of a wireless plan. These include antennas, access point placement, security, availability, and any potential obstructions.

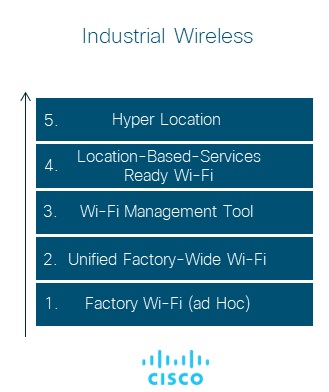

Industrial Wireless

2) Choose the right equipment. Enterprise-grade wireless equipment is not built with extreme conditions in mind. In an industrial setting, that equipment could fail. Even worse, it could interfere with day-to-day manufacturing operations. There’s a good reason almost everything in an industrial setting meets ruggedised standards. The same should be true for your industrial wireless infrastructure. Off-the-shelf wireless equipment might seem like a more cost-effective answer at first. However, equipment that does not meet industrial standards may be unreliable, and could cause the network to fail or become difficult to manage. Ensure that your equipment meets industrial ratings and is certified for industrial environments (Class 1, Div2, IP66, and IP67 are examples). You should also consider the proper antennas that will meet the range, coverage, and connectivity you need.

3) Bring IT and operations together. Historically, operations and IT have seen little convergence. They often manage different, segregated networks. However, it is critical to any wireless project that operations teams and IT teams collaborate. Together, they can coordinate priorities, overcome organisational inertia, and prepare for change management. IT and operations should work together on all aspects of network design, deployment, and management. This collaboration ensures that the wireless project will meet the needs of the factory floor. At the same time, it can build trust between the two functions and help operations leaders understand the capabilities of IT.

4) Plan security at every level of the solution [see “Securing your industrial network”]

The top 3 misconceptions about industrial wireless

Common misconceptions about wireless in industrial environments include: reliability, security, bandwidth and latency/throughput.

1) Reliability: lingering concerns regarding radio interference on wireless networks have put off some industrial customers. However, today’s wireless networks have matured and now support many mission-critical applications.

2) Security: is paramount for industrial operations, and some manufacturers see wireless as a potential security threat. They worry it will create new vulnerabilities in the network. One key concern revolves around rogue access points. Wireless intrusion-detection and intrusion-prevention systems (wIDS/wIPS) address this issue, by detecting, locating, mitigating, and containing wired and wireless threats through layers 1 to 3 (physical, data-link, and network).

3) Bandwidth: Manufacturers need support for high-bandwidth applications such as real-time data, collaboration, and video. Wireless can meet those high-bandwidth requirements through a variety of technological advancements. For instance, intelligent routing allows the access point to sense the best possible path for each packet of data. Newer standards offer increased bandwidth over a greater range.

4) Latency: To achieve low latency and higher throughput within wireless networks:

- Identify the number of nodes, clients, and devices to manage the amount of traffic across the network topology.

- Reserve bandwidth for specific mission-critical applications and peak access hours.

- Identify what industrial protocols are being used and which are better suited for wired or wireless environments.

- Correctly mount access points – ideally away from areas where there is high interference (5GHz frequency bands are generally better than 2.4GHz for industrial networks. They have more channels and are less prone to interference.)

Read more in this guide to industrial wireless

About Cisco and Routeco

Cisco provides the simple, intelligent, secure platform for industrial customers to improve business operations through Industry 4.0:

Routeco is an IoT Industry Expert Specialised Partner of Cisco. With experience of industries such as manufacturing, energy and utilities, travel and transport, connected safety and security, Routeco’s understanding of Cisco’s IoT platform provides industrial customers with the IoT solution they need.

About the authors:

Gordon Davies, Marketing Manager, Cisco with contributions from:

Cisco Industries Marketing

Cisco IoT Go-To-Market

Check out Part 3 which addresses industrial security

Contact Details and Archive...